Many of us have some familiarity with terms like Mechanical Engineering, Electrical Engineering, Chemical Engineering, and Civil Engineering. However, the term “system engineering” is not as common for many of us. This concept, though, has been around for decades, with the term first being used in the 1940s.

Many of us have some familiarity with terms like Mechanical Engineering, Electrical Engineering, Chemical Engineering, and Civil Engineering. However, the term “system engineering” is not as common for many of us. This concept, though, has been around for decades, with the term first being used in the 1940s.

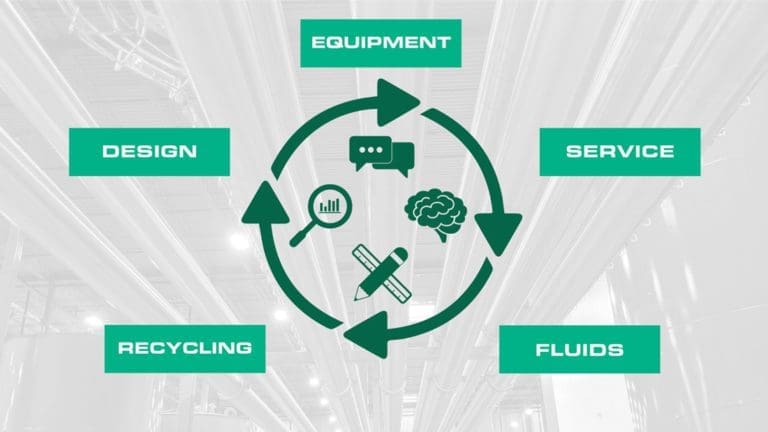

System Engineering is not so much a branch of engineering. It is a technique that uses the ideas, knowledge, theories and models from engineering disciplines and other sciences. It looks at the full process of a system – how each component serves a purpose, but also is a significant part of the whole. For example, a mechanics shop gets fluids from a provider, stores that fluid for use with customers and then recycles it. Although they are all individual parts, they are also part of an overall system.

Design

The System Engineering process begins with figuring out how everything can be interconnected. It’s not only finding the right equipment to meet your needs but it’s also figuring out how to place that equipment so it works best in your shop. By designing equipment and the operations, you can streamline how it works – and, more importantly, how it works best for you.

It is important to note, though, that equipment design and layout may not be your expertise. You are very good at machining parts, servicing vehicles, manufacturing, or whatever your business is built around. But figuring out where to place the equipment may require a different level of expertise. Plus, there are permits required, compliance regulations and other behind-the-scenes factors.

Fortunately, there are partners available to help. At Lube-Tech, we collaborate with you every step of the way to see your vision become reality. Whether you are tackling new construction or equipment upgrades, our experts are here to guide you.

Equipment

Equipment

You know how important it is to have equipment you can trust, and a high performing facility typically operates with premium equipment. But, installing new equipment can be complex, so it is important to have a partner that can guide you through the process. You’ll want help with choosing the right machinery, installing it in the right place, complying with regulations and taking care of all the paperwork.

Even if you don’t have new equipment, you still want and need your equipment to be working in peak condition. The machines in your shop should be monitored, maintained, and serviced regularly. Just like a vehicle that has routine oil changes and other work done based on mileage, your equipment needs to be treated just as well, if not better. Understanding the service and service interval of your equipment is the key to optimal performance.

Service

A clean fluid system provides better machining, surface finish, and tool life than a dirty system. Metal shavings, dirt, tramp oil and even bacteria are all problems that can escalate over time. And each of these issues can warrant a cleanout. Sometimes a cleanout is inevitable, but proper maintenance can help prolong machine life.

Maintaining your equipment can be a time-consuming task. And, depending on what type of machinery you’re running, it can be complicated.

Maintaining your equipment can be a time-consuming task. And, depending on what type of machinery you’re running, it can be complicated.

For example, shops that have coolant sump tanks need to do regular maintenance on the equipment to minimize bacteria. Although cleaning tanks is something you can do yourself, it can be a dangerous, complicated, and time-consuming process. Generally, it is a job that no one in your shop will look forward to doing.

If you clean your own sump, it will take anywhere from five to eight hours. That’s essentially an entire shift that your equipment is unavailable for use. Furthermore, the entire time, your employee is subjected to the fumes, stink and dirt coming from the machine.

A professional service technician, on the other hand, can generally complete the job in about two hours. This dramatically minimizes downtime and reduces your overall labor costs.

Fluids

The other key to equipment performance is to use a high-performing fluid to lubricate machinery. The primary role of a lubricant is to make things run smoother and without friction. But a lubricant also works as a coolant, a cleaner, protects against wear and corrosion, assists in power transmission and helps preserve component seals. If you do not monitor your machines as closely, make sure to use a robust fluid that can handle all types of applications, go without routine maintenance and run in extreme operating conditions without issues.

Because of the complexities of machines, an off-the-shelf oil is not going to provide the protection necessary to keep high technology machines running in peak condition. Rather, you should work with a trusted fluid developer to find the right mixture to make sure machinery is operating efficiently.

Not all fluids are created equally and it is important to find one that is best for the machinery you use. By working with the right partner, manufacturers can run a fluid analysis and find fluids that are optimum for the machinery used.

Recycling

Finally, there’s the issue of dealing with the old fluids. Whether you’re an automobile dealership, quick lube, maintenance shop or a manufacturing facility, you understand the issues surrounding used oil and fluids. Waste management can be a complex and confusing task.

Fortunately, it doesn’t have to be.

Finding a reliable team of experts to handle your fluid recycling takes a lot of pressure off you. Regulations, scheduling, and other matters related to waste management can be a thing of the past.

One-Stop Shop

The whole concept of system engineering is having that one source to take care of all these needs. Finding a partner that can handle each step of the process for you is a game-changer.

Here at Lube-Tech, we’re proud to be able to be the one-stop shop for all your needs. Contact us to learn more about how we can help you optimize your system engineering.